Полезное:

Как сделать разговор полезным и приятным

Как сделать объемную звезду своими руками

Как сделать то, что делать не хочется?

Как сделать погремушку

Как сделать так чтобы женщины сами знакомились с вами

Как сделать идею коммерческой

Как сделать хорошую растяжку ног?

Как сделать наш разум здоровым?

Как сделать, чтобы люди обманывали меньше

Вопрос 4. Как сделать так, чтобы вас уважали и ценили?

Как сделать лучше себе и другим людям

Как сделать свидание интересным?

Категории:

АрхитектураАстрономияБиологияГеографияГеологияИнформатикаИскусствоИсторияКулинарияКультураМаркетингМатематикаМедицинаМенеджментОхрана трудаПравоПроизводствоПсихологияРелигияСоциологияСпортТехникаФизикаФилософияХимияЭкологияЭкономикаЭлектроника

Symonenko S.V., English language advisor

|

|

The article describes the process of development and production of the model of the main building of Tavria State Agrotechnological University with application of different computer software.

У статті розглянуті процеси розробки та виробництва макета головного корпусу Таврійського державного агротехнологічного університету з використанням прикладного програмного забезпечення.

Topicality of the problem. Specific tasks to be solved in the sphere of material production dictate the need to have variable computer software for various purposes. A major problem is the creation of information systems in which information created in one program may be directly perceived and interpreted into another one without any changes.

The work demonstrates the ability to create complex projects using software packages of different companies - producers giving the example of the development of the model of the TSATU main building.

Research. The object of our research is the functionality of the computer-aided design programs for various purposes. The subject of our research is the layout design of the TSATU main building with application of different application software packages.

To implement the task we took the construction plan (Fig.1) of the building and designed the drawing in AutoCAD. The drawings were imported into Autodesk 3ds Max Design software environment, where the polygonal model of the building without architectural elements was developed.

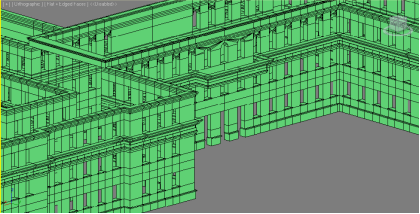

Then we reconstructed photographs of all architectural elements in Autodesk 3ds Max Design. Due to the large number of parts that are repeated, it was the design decision to create a common element, namely a column, a window, a baluster, pilasters, roof tiles, eaves. Further, these designed components were reproduced and placed in their places. As a result we obtained the photorealistic model in the scale of 1:50 (Fig.2).

Fig.1. The construction plan of the main building of TSATU

Fig.2. The 3D model of the main building of TSATU without architectural elements

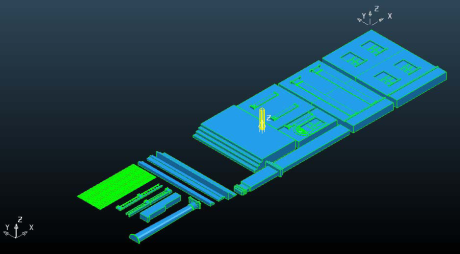

The assigned task was to provide the minutest details of the architectural elements of the building with the utmost precision. For this purpose the three-dimensional model of the building was imported into the package PowerMill (Fig.3) through the auxiliary module Exchange 581002 format IGES.

Fig.3. Import of 3-D models into PowerMill

The necessary tools were created, the trajectories were calculated and the appropriate cutting conditions were selected. Next, using different processing strategies control programs for manufacturing all the architectural elements of the building were developed.

The treatment was performed on the CNC machine. The machine was assembled from components that were bought separately, thus saving about 60% of the equipment cost. Therefore, a special postprocessor was developed to handle the created model. The postprocessor allows to convert data of the cutting tool position designed with the CAM-system to specific machine codes (G/M-codes) taking into account the features of its kinematics.

After processing of different model making option, it was decided to make it of gypsum. To fulfill this task initially molds were made of hardwood with the help of programs developed in PowerMill. According to the obtained structures two-component silicone molds for casting gypsum were produced. The required number of architectural elements was cast from gypsum in silicone molds, and then their assemblage was performed.

Processing of wooden structures was carried out using the technology of high-speed milling cutters with diameters from 1 to 3 mm.

Created molds were used for casting elements of the building with gypsum of Knauf company. After making the required number of elements of the building the assemblage of elements was implemented. After the assembly was completed the product was treated by an initial primer, and then was painted in colors that matched the colors of the real building.

The model length is 2700 mm. Its production took more than 50 kg of gypsum.

Conclusion. In the process of the main university building model was created, at the design phase Auto CAD and 3Ds Max were used. The project was carried out using PowerMILL software, a special postprocessor for CNC machine tools was also developed.

Work efficiency was achieved through the use of software from different vendors with further import of models from one development environment to another. It is possible to improve the programming process of processing parts of complex configuration for equipment with numerical control.

The methodology for design and manufacturing models using different software functionality was designed. This methodology is going to be used to create monument models and other architectural constructions.

УДК 504.054=111

Date: 2015-07-25; view: 407; Нарушение авторских прав