Полезное:

Как сделать разговор полезным и приятным

Как сделать объемную звезду своими руками

Как сделать то, что делать не хочется?

Как сделать погремушку

Как сделать так чтобы женщины сами знакомились с вами

Как сделать идею коммерческой

Как сделать хорошую растяжку ног?

Как сделать наш разум здоровым?

Как сделать, чтобы люди обманывали меньше

Вопрос 4. Как сделать так, чтобы вас уважали и ценили?

Как сделать лучше себе и другим людям

Как сделать свидание интересным?

Категории:

АрхитектураАстрономияБиологияГеографияГеологияИнформатикаИскусствоИсторияКулинарияКультураМаркетингМатематикаМедицинаМенеджментОхрана трудаПравоПроизводствоПсихологияРелигияСоциологияСпортТехникаФизикаФилософияХимияЭкологияЭкономикаЭлектроника

Задание 5.6 Put the verbs in the Past Tense

|

|

1. take

2. describe

3. understand

4. wash

5. make

Методические рекомендации:

Выполнение заданий к тексту требует его общего понимания. Контроль понимания достигается через выполнения этих упражнений. Информация, извлеченная при прочтении, текста может быть использована студентами в последующих заданиях.

Рекомендуемая литература: 1 осн. [54-62], 4 осн. [68-75]

Контрольные вопросы:

1. What are the features of letterpress printing?

2. Describe process of printing plate manufacture.

3. What is a crosslink?

4. What is the most prevalent printing plate?

5. Describe the operational steps for making the Nyloprint plate.

Тема 6: Print Finishing Processes

Задание 6.1 Read the text:

Finishing (postpress) is a segment of the print production flow in which the printed product is given its requested features of form and functions. The end products produced in the finishing process are therefore characterized by the design (shape) and the functions that are determined by the information content.

The following products are produced in the finishing sector (the information content is not taken into account):

• Individual sheets – trimmed sheets, cuttings;

• Folded sheets – sheets in various sizes that are folded according to a certain, sometimes complicated pattern;

• Newspapers – gathered folded sheets;

• Booklets – inserted folded sheets with a cover, stitched with wire or thread in the spine, secure binding;

• Brochures – single or multi-layer blocks, stitching or perfect binding, cover (mostly

made of heavier stock);

• Hardcovers – multi-layer block, thread stitching or perfect binding, cover consisting of several parts (usually referred to as a book);

• Assortment of sheets – binding technique: mechanical (very often detachable), comb or spiral bindings using metal or plastic;

• Packing material/means – open or closed material, cut to size and formed to hollow

bodies during the packaging procedure.

Printed products, in particular book binding products are usually assembly products, that is, they consist of several partial products that have been produced independently of one another:

• Block Carrier of the printed information (book block, content sheets);

• Cover Protection unit connected with the body (case, cover, file, folder, lid) or packing material;

• Finished parts Structural parts made of metal, plastic, board, etc., which need to be attached to the product (e.g., binding mechanisms in files);

• Supplements Information and advertising material that is added to the body or the finished product (inserted, glued). They differ considerably in their shape and comprise graphical products (e.g., cards, booklets), mailings, and samples;

• Jacket A jacket that is put around the actual cover of books and brochures.

Today jackets serve mainly for advertising purposes. To analyze the organization of the processing procedure it is useful to structure the finishing process into individual process sections. Each section characterizes the transformation of the material (partial product) with regard to the desired processing outcome. The designations of these processing sections use unique terminology that has historical origins.

Rausendorff made a suggestion for a process classification in bookbinding (table 1).

Table 1. Overview of the process classification in bookbinding

This structure can also be used for other print finishing processes.

The following operations are carried out in the process sections:

Cutting of webs and sheets

Paper webs or sheets are cut to a format that is suitable for further processing.

Folding

Sheets or webs (book binding sheets) are folded once or several times so that connected folded sheets or webs are produced at the folding edges.

Forwarding

Forwarding comprises all operations on the folded sheet where a jointing procedure

takes place.

Preparing processing and functional points

Separating or forming operations are carried out on partial products to prepare processing or functional points:

• rule perforation as tear-off, gluing or bending edge,

• hole punching for positive jointing operations,

• scoring, grooving, creasing to fix a bending edge.

Gathering to blocks

Producing an unbound block of independently produced and folded sheets of a book

or brochure in the correct sequence.

Binding blocks

Creating a temporary or permanent connection of the collated folded signatures/ sheets to a block by a jointing operation.

Cutting blocks

(Also referred to as trimming.) Blocks are trimmed to the end format on three sides.

Rounding blocks

Forming book blocks so that the block spine has a convex and the front trim a concave shape in the block thickness direction.

Coloring edges

One or more block edges are covered for coloring with an ink or metal foil.

Jointing extra components

Book marks, headbands (ornamented bands), or similar materials are attached to the block.

Trimming case material

Trimming cardboard covers, book cloths, and inserts for the case-making process or trimming of jackets.

Jointing covers

Making a book case by jointing the cover cuttings.

Surface finishing covers

Printing or embossing covers or jackets.

Rounding covers

The cover spine is rounded in a forming operation to conform to the rounding of the block spine.

Casing in

Jointing procedure of book block and case.

Forming the product

Comprising procedures for stabilizing the glued joint, forming an opening hinge (fold) and carrying out the book spine rounding

Completing the product

Including putting on a jacket, inserting supplements, and sticking labels onto the cover or the jacket.

Packing the product

The products are packaged individually or in piles; packing of the transport unit (pallet packaging). The process sections have been assigned with symbols (pictogram) that are used in the following to illustrate the process flows.

Figure 8 shows an example of a manufacturing process for hardcovers for fancy books. In practice we can distinguish between categories such as fancy books, simple edition bindings, school books, children’s books, and so on, which reflect the degree of complexity of the book blocks and the extent of surface finishing of book covers. The diagram (fig. 8) describes the production process for fancy books from print sheets. All process sections inside a red box are essential for the production of hardcovers and represent simple edition bindings.

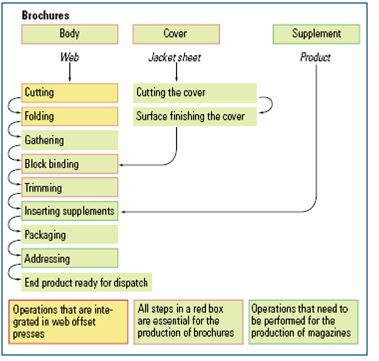

Figure 9 shows a possibility for processing brochures. It becomes obvious that the assembly of block and cover takes place during the block binding process. All process steps in a red box are essential for the production of brochures. Those process steps in a green box are typical operations for the production of magazines. In a description of the processing steps of newspapers, the operations for the production of the cover, block binding, and trimming would not take place.

The collection of loose leaves in a binder is described in another example. For the most part the same operations are carried out as in the previous examples. The preparation of functional and processing points includes the producing of binding holes in the spine of binders and punching the block as a preparation for the positive joint/linkage between file and block by means of a mechanism.

Figure 8 - Process steps for the production of fancy books

To assess a process step it is necessary to investigate the technical means (tools) used for the transformation of the partial product. The way a material is changed by a tool is referred to as the working method.

A selection of working methods applied in finishing is listed in table 2. A process step can in principle be achieved by several working methods. The “block binding” process step can be achieved by the working methods: stitching, gluing, or clamping, the “surface finishing” process step can be achieved by the working methods: printing or foil embossing.

Figure 9 Operations for the production of brochures

Table 2 Overview of method groups and working methods applied in finishing

The description of methods makes finishing comparable with other engineering sciences since they apply the same working methods (e.g., scoring, diecutting, milling, welding, spraying). But there are also working methods, such as folding, pleating, perfect binding, crimping, or gathering, that are exclusively used in the graphic arts industry. In these cases the process section and working method have an identical designation. For the description of finishing processes, logistics processes (loading, unloading of machines, transporting, temporary storing of semifinished products and products) must be considered.

Задание 6.2 Find the proper Russian equivalents for the following terms:

| 1 semifinished products | a. Переплетная крышка |

| 2 jacket | b. Полуфабрикаты |

| 3 Cutting block | c. Сфальцованные листы |

| 4 cover | d. Кругление блоков |

| 5 Folded sheets | e. суперобложка |

| 6 Rounding blocks | f. Обрезка блоков |

Задание 6.3 Find the definitions of the words:

| Packing material/means | a. inserted folded sheets with a cover, stitched with wire or thread in the spine, secure binding |

| Individual sheets | b. open or closed material, cut to size and formed to hollow bodies during the packaging procedure |

| Newspapers | c. a cover for holding together sheets of paper |

| Booklets | d. trimmed sheets, cuttings |

| binder | e. gathered folded sheets |

Date: 2016-07-18; view: 381; Нарушение авторских прав